I’m going to present to you, a type of mash tun you’ve ‘never’ seen before. It works great! I will include efficiency stats at the end.

Even though I just made this brand new mash tun, I plan on making a unique brew-in-a-bag ‘system’ out of my 16 gallon boil keg for my very few 6gal + batches. I will make a video on that when I’ve completed the project.

I wish to state for the record, that I do ‘NOT’ recommend any home brewer to go out of their way, and mash grains in this manner. The reason I say this, is that the amount of work involved to make this mash tun run in a ‘sanitary’ / ‘efficient’ manner is much more time consuming than should be allowed by law. lol.

I’ve been brewing this way for quite awhile now so, for me, the extra work does not take very long and the pay off is worth it in the end. I’m posting this strictly for ‘your’ entertainment and educational purposes only.

Background Story Stuff Bla, Bla, Bla…

When I started doing all grain brewing I, for whatever reason, never had any luck pouring hot water in a cooler, then add the gains, and so on…

Like most people struggling, I said to myself… “STOP THE MADNESS!!!… There’s got to be a better way!” What I really wanted to do was raise the temperature in the pot in order to mash the grain but, how do I get wort out of a pot full of grains?

With that thought, I got the ‘hot’ idea to pour the grains into the pot of hot water, raise the temperature, then dump it all into the cooler. No problem right?

I got a rectangle 10 gallon cooler my parents were going to throw out and purchased the hardware to convert ma and pa’s cooler onto a rock’n mash tun! Cool!, right?

So, I dumped the hot grain / water mix (@ about 155F) into the cooler, and waited an hour or so. So far, so good!

I opened the mash tun (A little over an hour later) took a temperature reading and the the first thing that went wrong was that the temperature dropped further than I was expecting. I closed the cooler at around 150F and the temperature dropped 5 – 7 degrees. Not the end of the world but, I didn’t expect that much heat loss.

The next thing that went wrong was a big deal. The damn mash tun was ‘almost’ stuck. It seemed to take half the day to collect that sweet wort from the mash. So, sparging the mash went out the window right then and there.

This ‘sticking of the mash tun’ didn’t make any sense to me since people use coolers all the time to mash out their grains in. I could only conclude that the ‘force’ of all the contents dumped onto the screening while pouring has an effect on clogging the mash tun.

How do I keep the mash tun from clogging? Then, for better or for worse, the light bulb moment happened. Hydrology!

Growing up in Colorado, my father would take me to some of the really big jobs he was working on. One of these jobs was a big damming project. I remembered they used rock to ‘filter’ derby from getting into where the water would be used to spin a turbine or just regulate the water flow.

I decided that since I had a dump truck amount of 1 – 2 inch granite rock in my backyard, I would use that rock to ‘shield’ the mash tun filter from the force of dumping the grains onto it. I know your saying… “NO! Don’t Do It! but, I did do it. It works great, and below, I will show you how I fitted my second mash tun to run with a hydro system and explain some upsides you might not have expected.

Constructing The ‘Double’ False Bottom Mash Tun

Someone was going to throw out this perfectly good 10 gallon Gott cooler so, I was able to save it from the dumpster.

I got all the valve and gasket hardware to convert it into a mash tun and, the first thing I noticed was that the amount space from the valve port to the bottom of the cooler was over a half inch. I wanted to fill that space mainly to give my screening system proper support. Also, that waisted space would provide enough sweet wort to fill my hydrometer cylinder. So, why waste it?

First False Bottom Of Double False Bottom Mash Tun.

Above is the first ‘false bottom’ made from food grade plastic which sits at the very bottom of the cooler. raising the bottom of the cooler up to the level of the ‘bottom’ of the valve port.

I special ordered the plastic from a company that uses this material for custom made cutting boards. Lacking the tools, I could have paid the coin and had them cut the material ’round’ to fit perfectly into the cooler giving no gap, but I’m cheap and just cut the material with a hacksaw.

As you can see the ‘screening infrastructure’ rests nicely on top of the cutting board material.

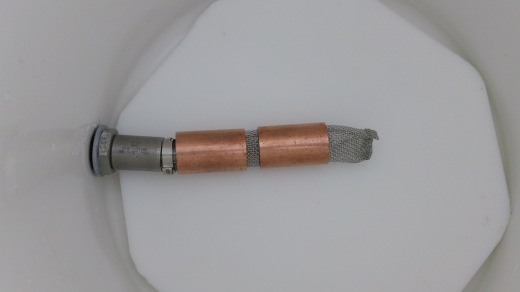

I found this screening system material for cooler mash tun conversion online. I really like the fact it is so porous. Normally, people would shy away from such porous screening for their mash tun. However, with my ‘hydro’ mash tun method, the larger screening material is desired because ‘it will NOT clog’!

To shield the screening material and protect it from the granite rock (ESPECIALLY WHERE THE SCREEN CONNECTS TO THE VALAVE COUPLING. IMPORTANT!) I use 5/8″ ID copper couplings.

I cut slots into the copper couplings and make sure to face them down towards the cutting board when place over the screening material.

SANITATION ABOUVE ALL ELSE!

Even outside this mash tun project, I spend as much time breaking stuff down and cleaning as I do brewing.

You’re sure to get a laugh out of this… I scrub these granite rocks with a brush and PBW, I then sanitize them before placing them into the mash tun. I have the most clean and sanitized rocks in the nation. I will assure you.

This is were my fellow ‘clean freaks’ are going to flip out. I really am a clean freak too, and have ‘never’ had an infected batch using this hydro method (yet), and I have done many, many batches using the rocks.

A Rock Solid Foundation!

The screen tubing is surrounded by 1″-2″ cleaned and ‘sanitized’ granite rock preventing the tubing system from moving when pouring the hot water and grain into the cooler.

A granite mash tun ‘second’ false bottom

The rock is stacked in such a way that the majority of the rock is piled on top where the tubing enters the cooler, giving the screening / tubing’s weakest point maximum protection from the contents being dumped onto it. The screening material will NOT budge. I always dump the grains to the opposite side where the tubing enters the mash tun.

The marbles were just extra material I had (for boil foam reduction) laying around so, I put it to work, for added filtering.

Rock at bottom of mash tun maintains heat!

One of the upsides I found by using this method of mashing grains is that the rock does not cause great heat loss when it absorbs the heat. However, the heat absorbed by the rock ‘radiates’ back into the mash, maintaining heat duration.

With this ‘hydro’ method I never used a blanket for heat loss yet. Outside temperature (brew day in photo) is 65F. Beginning temperature inside cooler 151F. After one hour + (a little over), inside cooler temperature was 148F. Very happy with that, since I never wrapped cooler in a blanket.

Makeshift sparge setup.

Since I changed my mash tun from rectangular to circular I have not yet converted my sparging apparatus for a circular mash tun so, I had to rig my sparge in this ‘less desired’ way. Here, I ended up flushing two, 1 quart or so, rounds of 170F water over the grain bed. Although, this was NOT my desired method of sparging, my efficiency, never-the-less turned out to be in the upper 70%! I strongly believe that my efficiency would have reached into the 80% without a hitch, had I sparged in a more ‘fluid’ and proper manner.

Photos below was my first time ever using this mash tun. It exceeded my expectations! Great operation and clarity!

Crystal Clear Wort Runnings!

Clear Wort Runnings In Tube.

You may find this interesting

With this particular batch, I ground organic non GMO blue corn as an adjuvant. This corn was ground to a fine powder. No problem for the hydro mash tun to handle!

LOOK! I CAN SEE THE VERY BOTTOM!

You can see the very bottom of the Kettle from the mash tun!